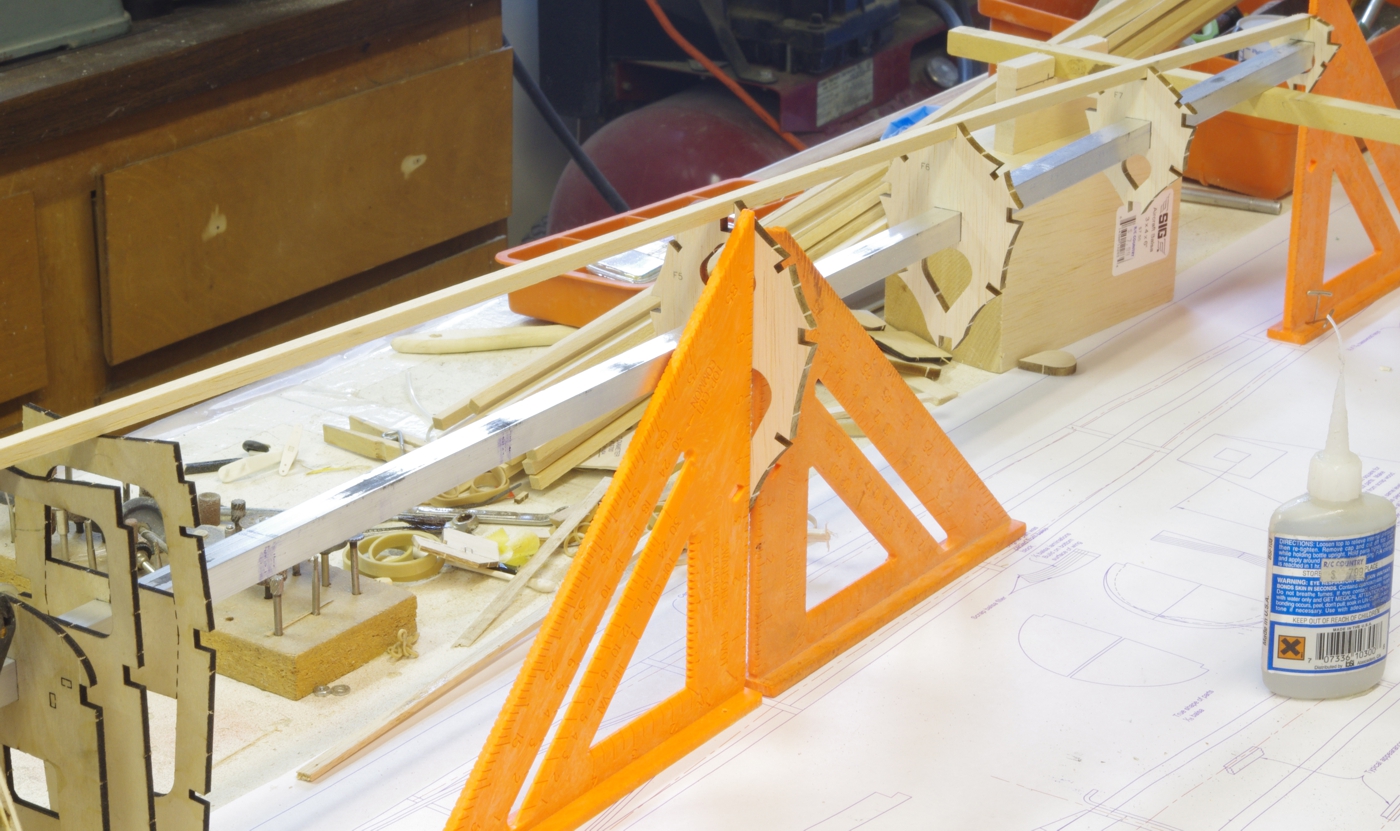

A front jig fixture was made up from scrap 1/4 inch plywood. The supplied square hole plate is on the other side. Since I didn't want to

take photos of an crooked jig I took some pains to get it level fore and aft and laterally. There is plenty of room at the tail for a 1/2 inch square length

of maple to run across on the rear support. A clamp was placed inside the front support to prevent the aluminum extrusion from moving.

A triangle is restraining the bar on the other end.

The jig is above the fuselage top view, and the triangles locate the F5 bulkhead as the top longeron is tacked in.

Remember to locate the top longeron at F5 so there is room for the tab on the top fuselage framing to fit beneath it.

From F5 aft the bulkheads can be done in any order, but the front ones are best done from F1 aft so there is room

for the triangles or whatever type of square you use.

I did the top and bottom longerons at the same time, then left and right. The side longerons will have to be spliced unless you have

48 inch stock, they measure a little under 43 3/4. Lastly the quartering stringers of 1/8 x 1/4 are installed. It is better to use flexible

stock as there is a twist from F3 to F5. There is a "wasp waist" on the top stringers at F5 that will want to draw out the stringer

between F6 and F7 slightly in reaction. A little sanding between F6 and F7 will correct that if desired.

A friend gave me the idea of using aluminum angle extrusions covered by plastic wrap to keep structures straight as they are

glued. It is especially helpful on built up spars but works well for simple jobs like joining longerons with scarf joints. I get

the angles the same by putting the companion sticks under a 3/4 square length of hardwood and applying the end to the belt sander.

(Probably a process everyone else came up with before me.)

The upper cabin framing has been laminated and is curing in place. I used Titebond for this. The inside faces

of the aft ends of the framing need to be tapered to fit in the notch in F5 below the top stringer.

Installing the fuselage keels. The notches for the landing gear go just in front of the bulkheads so the wires

will rest against them. The aft end is 1/8 inch above the lower longeron to allow the lower fuselage plate to

fair at that point. The landing gear must be installed before the bottom plate.